Over 50 years of age and we’re still playing with Silly Putty!

Seriously, Silly Putty? In a way, it is true, but this is our kind of “Silly Putty”. Here at Extrude Hone we call it Media and in fact Abrasive Flow Machining Media.

The origins of the media can be linked to what was then ‘Silly Putty’ in the early days of experimentation by Larry Rhoades, Extrude Hone founder. Today it’s much more than that and has evolved to something that is totally unique and unparalleled by other processes.

The properties of this material combined with abrasive engineering provide one of the most advanced cutting tools specially to reach areas that cannot be touched by any other methods. It’s used to polish open surfaces and radius edges delivering consistency and control for safer application.

Since Extrude Hone invented the Abrasive Flow Machining process in 1966, abrasive media has been at the heart of it.

Since Extrude Hone invented the Abrasive Flow Machining process in 1966, abrasive media has been at the heart of it.

Thousands of applications across all markets have taken advantage of the process and the media that goes with it. From aerospace OEM’s who for decades have been benefiting from the Abrasive flow uniqueness to increase the power of their engines, to the medical pioneers who process cardiac valves you will find a myriad of applications. Some applications are more conventional like flowing the inner passage of a hot runner for the plastic injection or polishing an aluminum extrusion die but, in both cases, they are hard to reach areas. Some require tooling to make processing possible or to increase efficiency by multiplying the number of components processed in a one shot. Tooling fixtures can also be designed to incorporate media flushing, making cleaning a breeze and suited for high volume production.

With the rapid expansion of Metal Additive Manufacturing we have been a key solution provider when it comes to improving surface roughness. We have no  problem in polishing and cleaning the deepest of internal channels the most complex organic manifolds. It’s not only internal, we also improve external surfaces, with proven solutions qualified in both Aerospace and Medical.

problem in polishing and cleaning the deepest of internal channels the most complex organic manifolds. It’s not only internal, we also improve external surfaces, with proven solutions qualified in both Aerospace and Medical.

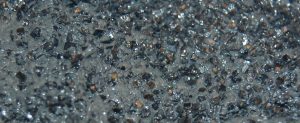

The Media Matters to us. It is so critical that we have developed over a thousand recipes. First, there are a range of different bases that can be used, from classic polymer to more recently oil free. Then the viscosity comes into the picture, taking a key role in the application, the stiffness addresses whether we radius or polish the part and we can tailor this to our customer’s needs.

Finally, the ultimate ingredient: the grits. Different material, different grit size, in different distribution that will give the best cutting efficiency based on the material that is being processed.

That’s why at Extrude Hone we talk about “media engineering” and “made on demand”.

In addition to this the machine itself will control the process that include extrusion pressure, temperature and volume extruded.

But, let’s get back to the media…

As this is such an important topic for AFM machine owners and customers looking into polishing, blending, radiusing, flow tuning we have now created a dedicated page on our website https://jp.extrudehone.com/media-matters . This page will provide you with educational content and will give you access to documentation you require.

We support you around the world with the media you need.

We support you around the world with the media you need.

We are the original and we are the best, remember that only genuine Extrude Hone media comes with our logo.

Media Matters, and there is nothing silly about it!