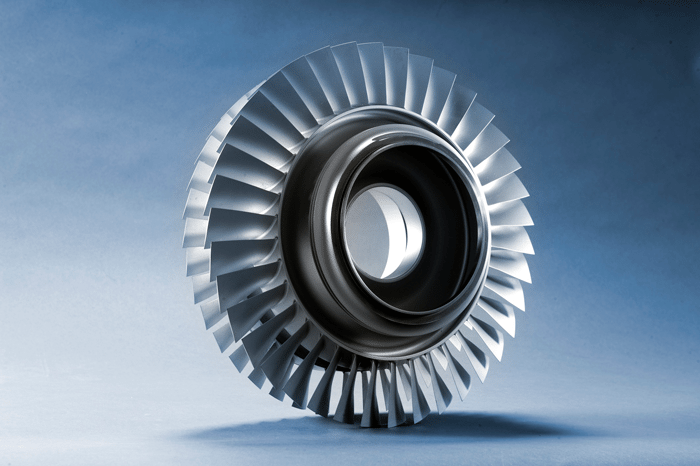

How ITP Engines UK and partners Brunel University and ExtrudeHone team up to get a mathematical model of the AFM process to size in the complex geometries of blisks.

As a supplier of fuel nozzles for next generation engines and components, you’re aware of the increasing emphasis to decrease fuel consumption and emissions through the increase of injection system pressures. The goal being to achieve a greater atomization of the fuel as it enters the engine. (more…)

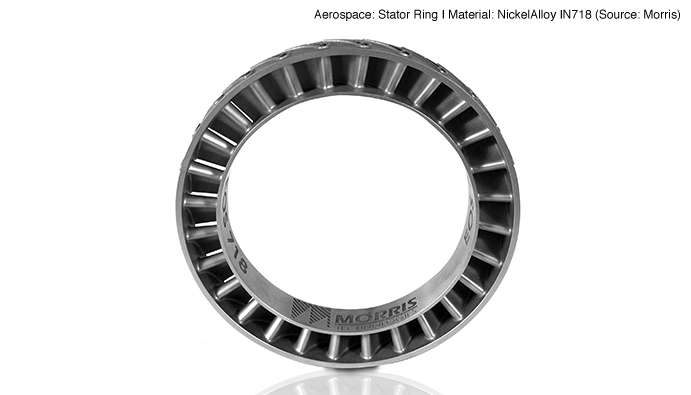

Additive Manufacturing

There is extreme interest revolving around Additive Manufacturing. Fully functioning cars were produced using Additive Manufacturing techniques during the 2016 IMTS Show in Chicago – demonstrating the process benefits of the AM Technology.

Additive manufacturing (known also under DLMS; SLM; AM, ALM, 3D Printing) is a process of building parts and components layer by layer, connecting powder particles via an energy source. (more…)

New thermal deburring machine. Extrude Hone brings – the T350 and T450 thermal deburring machines to  provide quick reliable solution for complete and simultaneous removal of internal and external burrs.

provide quick reliable solution for complete and simultaneous removal of internal and external burrs.

The challenges:

As 3D printers become more ubiquitous, the question manufacturers are trying to answer is not ‘how do we incorporated industrial 3D printing?’ but ‘how do we incorporate industrial 3D printing better than our competitors?’ Whether your application involves additive layer manufacturing (ALM) or laser sintering, the key that can set your

product above the rest is finishing. (more…)

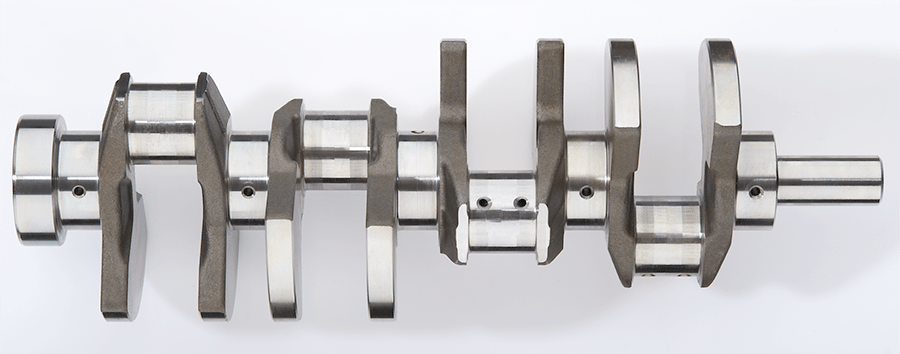

Improving Crankshaft Manufacturing with Electrochemical Machining

Ensuring sufficient and permanent lubrication of crankshaft bearings in automobile engines is critical for avoiding engine failures. As the crankshaft becomes smaller, due to manufacturing trends and consumer expectations, the number of oil intersection holes increases. All burrs and debris left behind in the drilling process must be removed.